3. Analog press

Semi-rotary offset Label press MLP

The ultimate solution for short-runs of high-quality labels. Entirely servo-driven system with fully integrated digital controls offers remarkable cost-efficiency.

Applications

・Food and beverage labels

・Cosmetic labels

・Wine labels

・Other labels in general

・Cosmetic labels

・Wine labels

・Other labels in general

Advantages

- Automated make-ready control system and repeat data management system offer dramatic reduction of material wastage and job changeover times.

- Largest-in-class repeat length of 355.6mm allows 3 times as high productivity as conventional semi-rotary machines.

- Refined ink train with 4 form roller delivers constant ink film on plate surface, thus achieving high-quality printing with minimized color variation.

Main Features

- Servo-driven infeed/outfeed system offers greater accuracy and stability of color-to-color register even after repeats of speed up/down.

- One-size blanket can be used for all repeat lengths, therefore job-by-job exchange of blanket is no more necessary.

- Electronic ink-key remote control system assures quicker color adjustment.

- Compatible with a range of substrates including clear-on-clear films.

Main specifications

| Model | MLP10A | MLP13A | MLP16A | MLP13C |

|---|---|---|---|---|

| Max. speed | 200impressions/min | 200impressions/min | 200impressions/min | 220impressions/min |

| Max. web width | 260mm | 350mm | 420mm | 350mm |

| Max. print width | 254mm | 330mm | 406mm | 330mm |

| Repeat length | 127.0mm ~ 355.6mm | |||

| Max. roll diameter | 600mm | |||

| Paper grammage | 50 ~ 265 g/m2 | |||

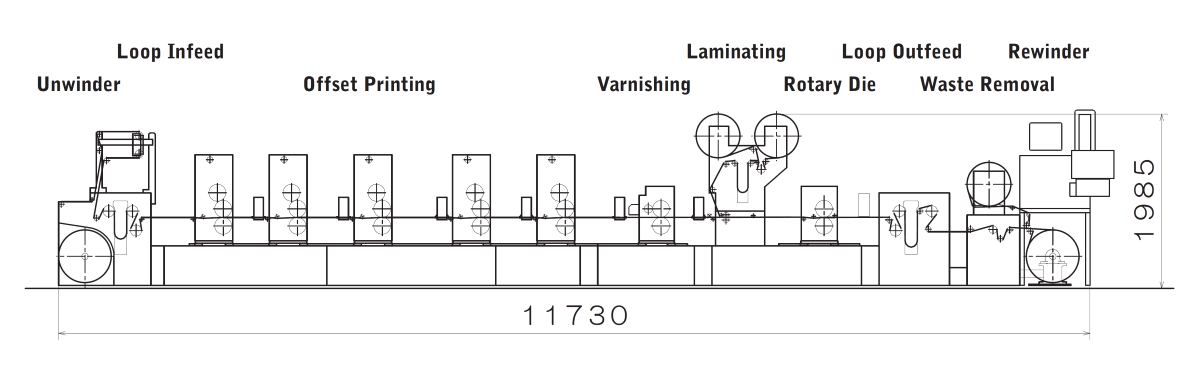

Machine composition figure

Optional units

・De-glueing unit

・Cold foil unit

・Hot foil unit

・Varnishing unit

・Embossing unit

・Laminating unit