EB web offset press MLP18-EB & MHL18-EB

Take full advantage of the conventional wisdom in offset printing coupled with EB curing ink innovations

Miyakoshi’s “MLP18-EB and MHL18-EB” are unique offset printing presses that offer superior running costs in small lot production and provides high reliability in environmental performance.

These 2 machines are web-fed line-type rotary offset presses featuring outstanding agility with EB (electron beam) irradiation devices and ink curing mechanism.

Being environmentally and economically friendly, both machines offer high utilization of capacity and a wide range of applications, which provides strong support for small & medium lot production of flexible packaging.

Benefits

Excellent operational efficiency and running costs

In addition to the low cost of offset plates, the job changeover time from the plate-making process to the start of printing are substantially shorter than gravure and flexography, boasting high operational efficiency and effectiveness in short- to medium-run production.

Wide range of applications

EB-curable ink is characterized by excellent adhesion to plastic film, heat resistance, scratch resistance, and alcohol resistance, and therefore it is reliable for a variety of applications in the flexible packaging field.

Environmentally friendly ink

Solvent-free ink means operator-friendly in press room and environmentally friendly. In addition, no explosion-proof press room is required, which is another advantage in capital investment compared to solvent-based ink systems.

Reduction of CO2 emissions

Compared to conventional solvent-based ink, the EB curing system uses less energy to dry the ink, contributing to the reduction of energy-related CO2 emission.

Reduction of capital investment for making offset plate

Use of process-free plates eliminates the need for chemical processing after plate imaging, thereby reducing the capital investment for plate-making equipment and at the same time reduces environmental impacts.

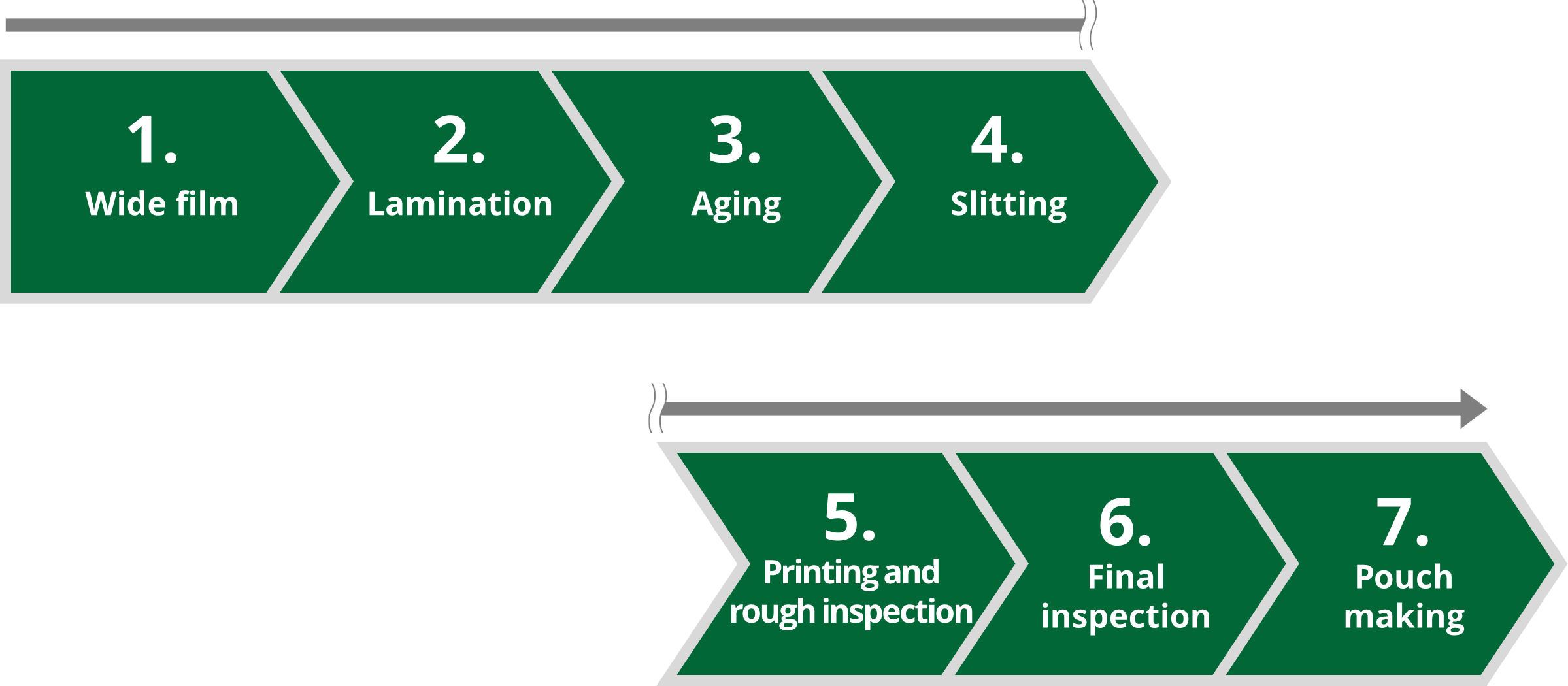

Pre-laminated surface printing

Surface printing offers sustainable future for flexible packaging. Bringing the lamination and aging processes BEFORE the printing process, time from order to delivery can be shortened. Furthermore, applying EB topcoat (varnish) after colors protects the surface color print more securely against scratches and abrasion. Surface printing provides development opportunities for de-inking.

Features & Configuration

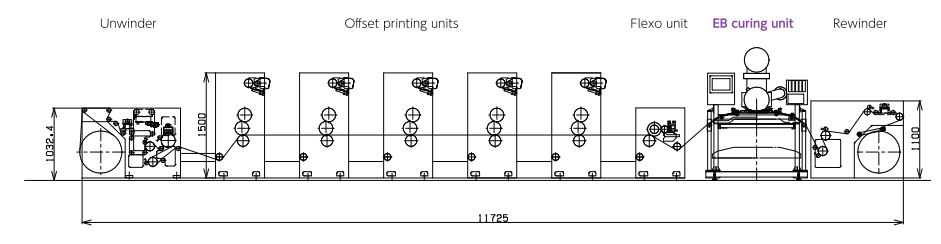

Semi-rotary EB Web Offset Press “MLP18-EB”

| Standard configuration | 5 colors+flexo coater +EB irradiation unit |

| Film transport | Semi-rotary |

| Max print width | 450mm |

| Repeat range | 215mm~406mm |

| Max printing speed | 200rpm *81m/min with max repeat size |

| EB curing | IWASAKI EC110/45/40mA |

| Option | AI assistant system for operators “yaless AI” *not included in standard specifications |

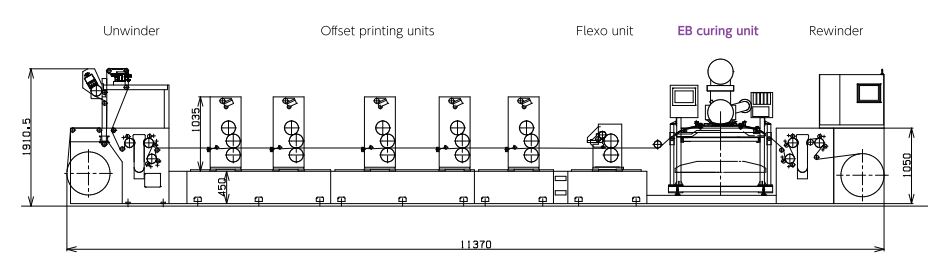

Rotary EB Web Offset Press “MNL18-EB“

| Standard configuration | 5 colors+flexo coater +EB irradiation unit |

| Film transport | Rotary |

| Max print width | 450mm |

| Repeat range | 380mm~610mm *variable sleeves are required |

| Max printing speed | 100m/min |

| EB curing | IWASAKI EC110/45/40mA |

| Option | AI assistant system for operators “yaless AI” *not included in standard specifications |